- 27 March, 2024

- Francisco Gallego

- Comment: 0

- News

COMPENSATION OF REACTIVE POWER IN PHOTOVOLTAIC PLANTS FOR COMPLIANCE WITH NTS

REGULATION:

The current regulations govern the necessary aspects for the implementation of the grid code for specific electrical installations.

Among these requirements based on the Technical Supervision Standard (NTS) and according to EU Regulation 2016/631, compliance with Reactive Power Capacity is mandated.

This requirement stipulates that an electrical plant must have the technical capacity to generate and absorb reactive power within a minimum range, from its installation to the connection point, in accordance with voltage control response.

SOLUTION:

OPTIONS

Considering the resistive and inductive nature of photovoltaic solar plants, the main challenge lies in compensating for the reactive power consumed mainly in the wiring and transformers of the solar plant, and in certain cases, even in the substation, while also generating enough reactive power to supply the grid.

To meet this objective, there are two main approaches to generate reactive power in a photovoltaic plant:

- Through Reactive Power Compensation Equipment.

- Using Available Generation Power.

In the first case, this includes batteries, automatic or fixed capacitor banks, STATCOM, DVR, among others. The required capacity will depend on the power flow to be compensated at the connection point, according to the grid code requirements for corresponding active power and voltage.

In this scenario, the installation will require a specific space, as well as all protection and connection elements. Typically, the connection of these devices is carried out at medium voltage and it is installed in a substation.

In the second case, reactive compensation is performed directly in the generation and conversion phase of the photovoltaic plant. For this, a higher power is needed in the plant than at the Point of Common Coupling (PCC), considering the following:

Peak Power (MWp) > Rated Power (MWn) > Power at PCC (MW)

This way, the total Peak Power of the solar panels must be greater than the Rated Power of the inverters, and in turn, this should be greater than the power at the Point of Common Coupling (PCC).

Although this method requires more solar panels, inverters, connection and protection elements, as well as a larger installation area, it offers the advantage of providing more active power during extended periods, thereby improving the overall performance of the plant.

In some cases, both compensation methods can be combined to achieve an optimized result, which requires a technical-economic study of both solutions. The choice of panel type and inverter can also influence this decision.

ESTUDIO

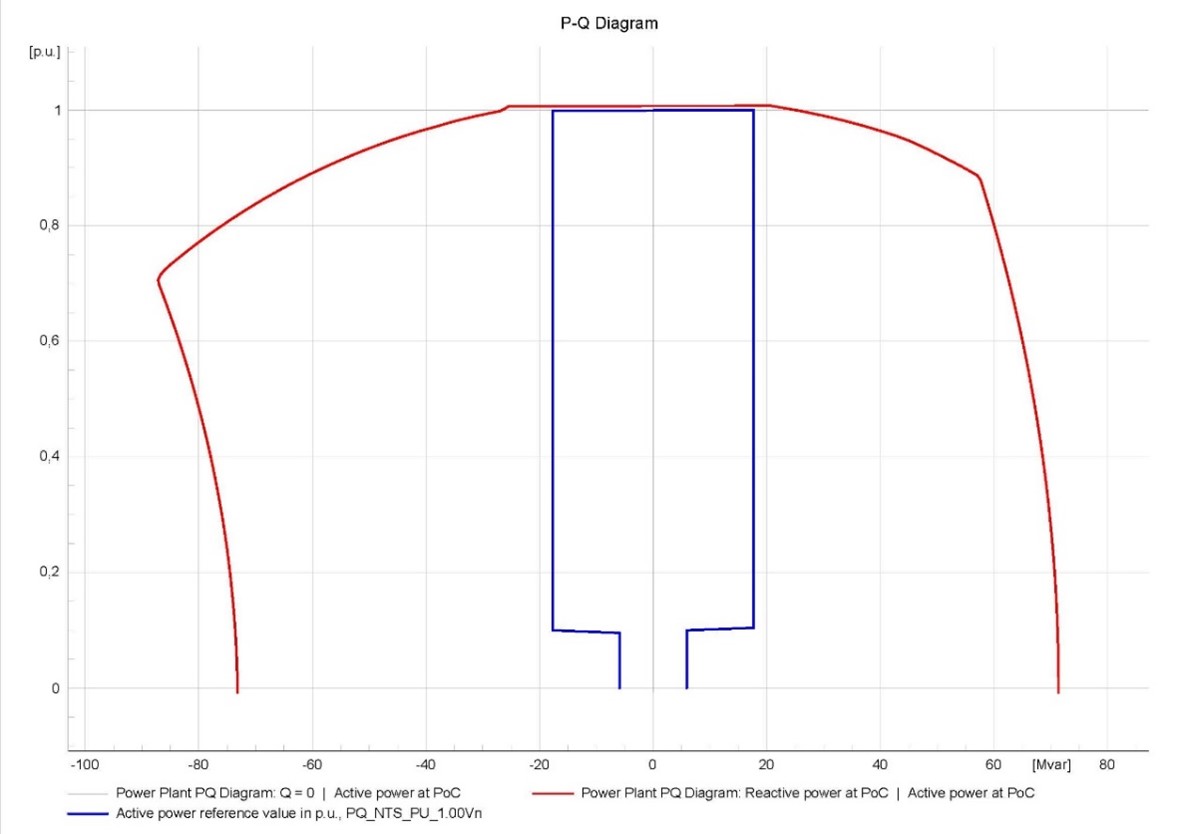

The validation of compliance with the grid code regarding reactive power compensation requires the execution of a dynamic load flow study. This study involves the use of specialized software capable of simulating the over-time behavior of the equipment that is part of the photovoltaic plant. | In this evaluation, a P-Q (active power versus reactive power) diagram is employed to analyze various scenarios based on voltage levels. Each scenario must be examined in detail, and the power response curve at the Point of Common Coupling (PCC) should surpass the reference curve established by the regulations to ensure compliance with the requirements. |

The graphical representation of these curves allows for a clear and precise visualization of how the photovoltaic plant behaves in terms of active and reactive power under different situations. This approach facilitates the identification of potential deviations from established regulations and the implementation of necessary adjustments to ensure compliance with reactive power compensation standards.

At MEP-Projects, we ensure customer satisfaction by comprehensively addressing the task of demonstrating grid code compliance. Our approach includes meticulous comparison with regulatory reference curves, and we collaborate closely with the client, providing detailed reports and transparent recommendations to ensure regulatory compliance and long-term system efficiency.

Made by Alfonso Mateos (Lead MEP-Projects Canada)